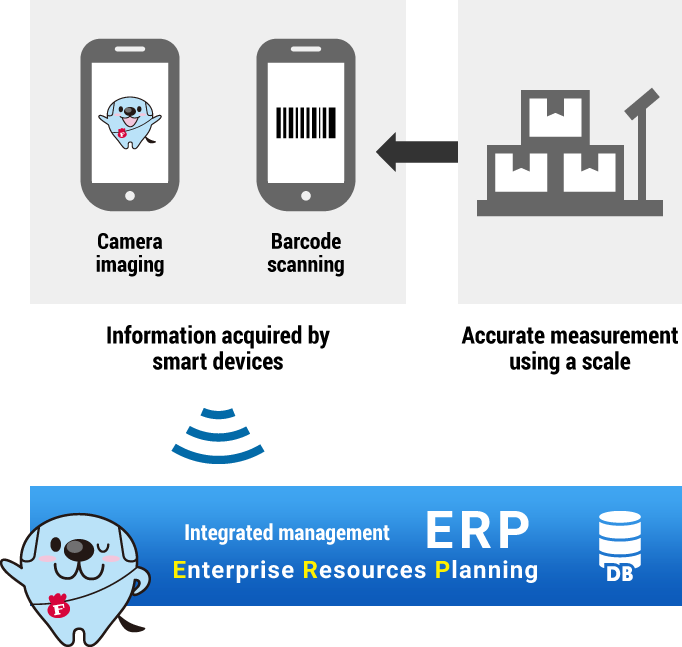

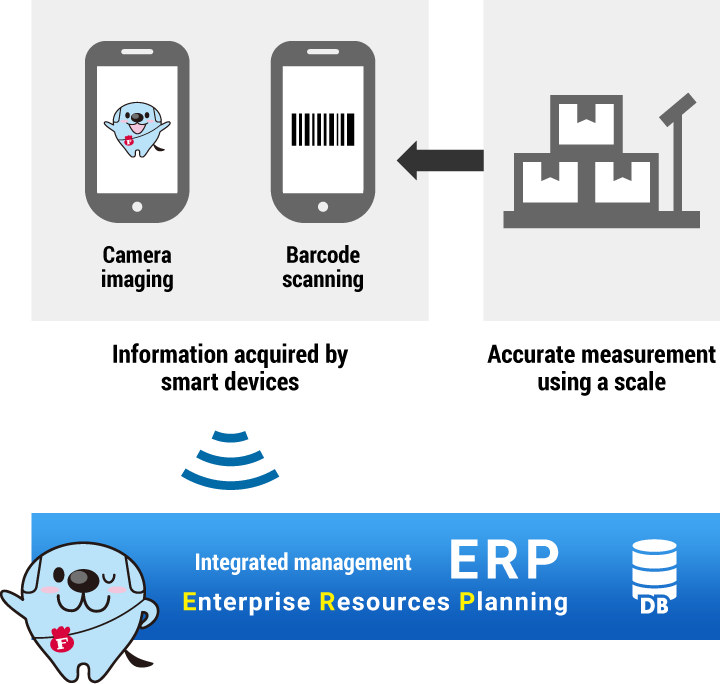

Managing highly precise information in an integrated manner

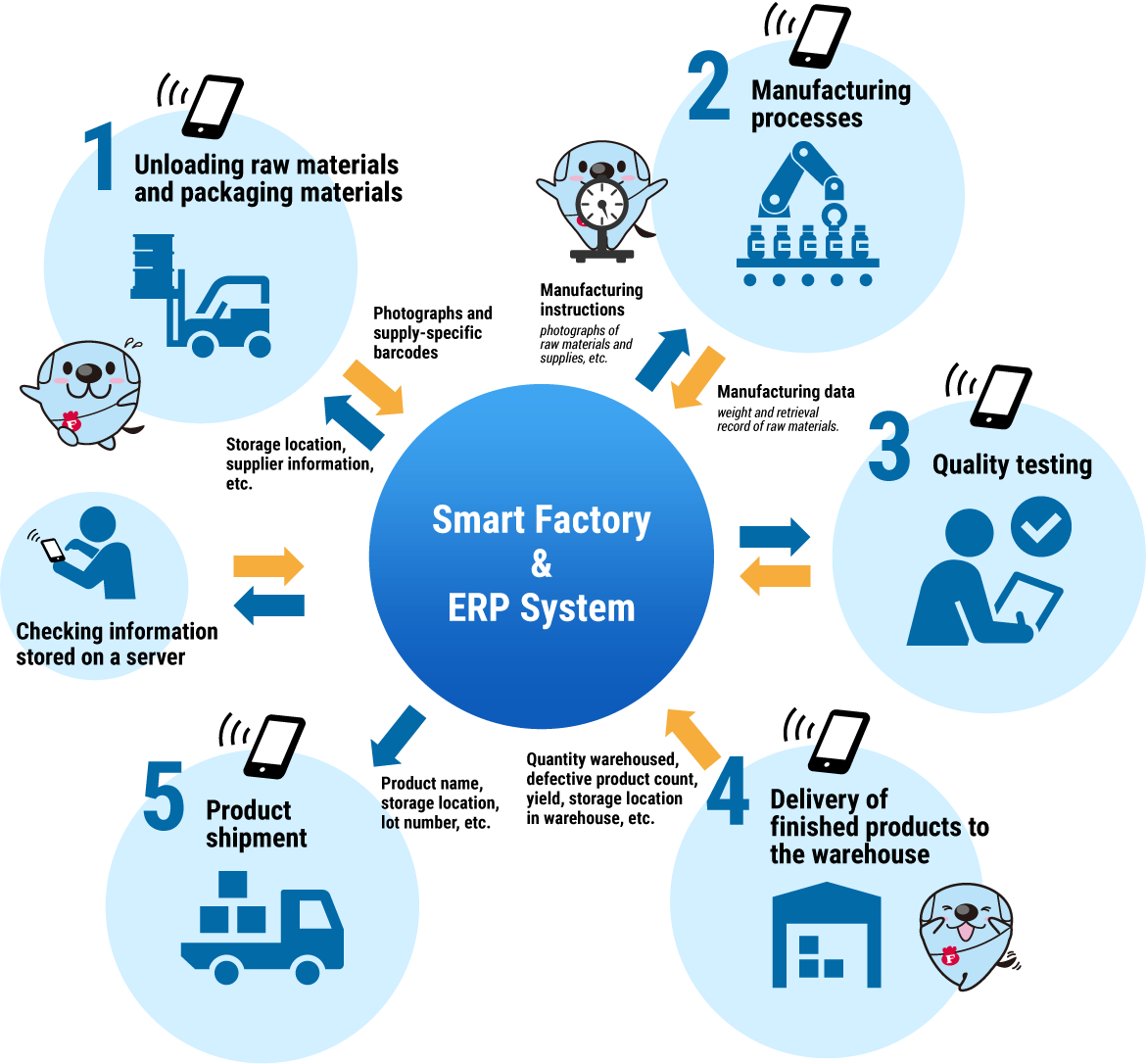

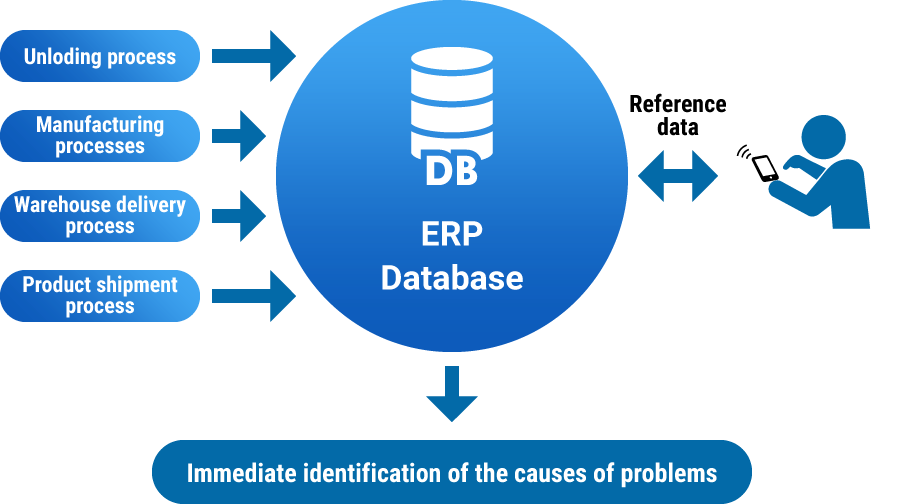

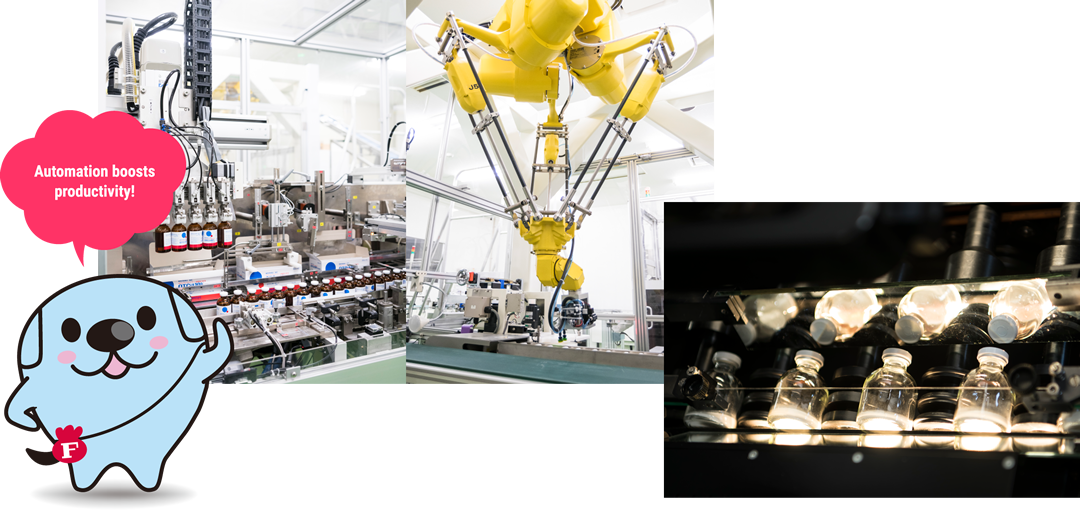

By connecting systems which is linked with peripheral equipments such as Smart devices'camera, barcode readers and scales to the ERP system we use to centrally manage information so that data can be updated in real time, we’re able to manage highly precise information in a centralized manner and streamline operations throughout our factories.